OUR OFFERING

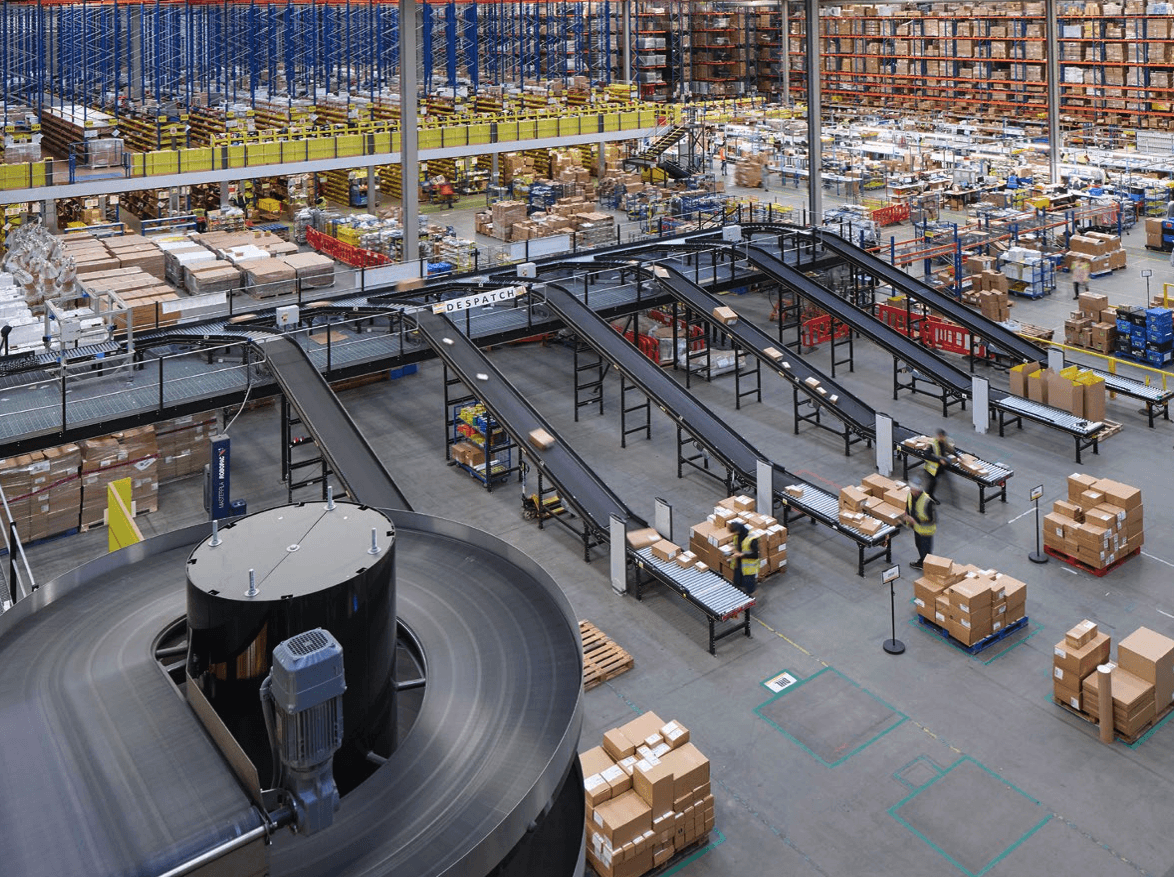

Case study George Clothing

In a pivotal project with George clothing at Asda Lymedale, AMH Material Handling expertly increased storage capacity and optimized e-commerce efficiency. This transformation led to a significant leap in operational capability, accommodating an extra 250,000 units and enhancing facility utilization over 1.2 million sq ft. Demonstrating agility and foresight, AMH ensured peak performance during high-demand periods, embodying innovation and operational excellence in the fast-paced retail sector.

250,000

Units storage Capacity Increase

1.2 million

sq ft optimized Facility Utilization:

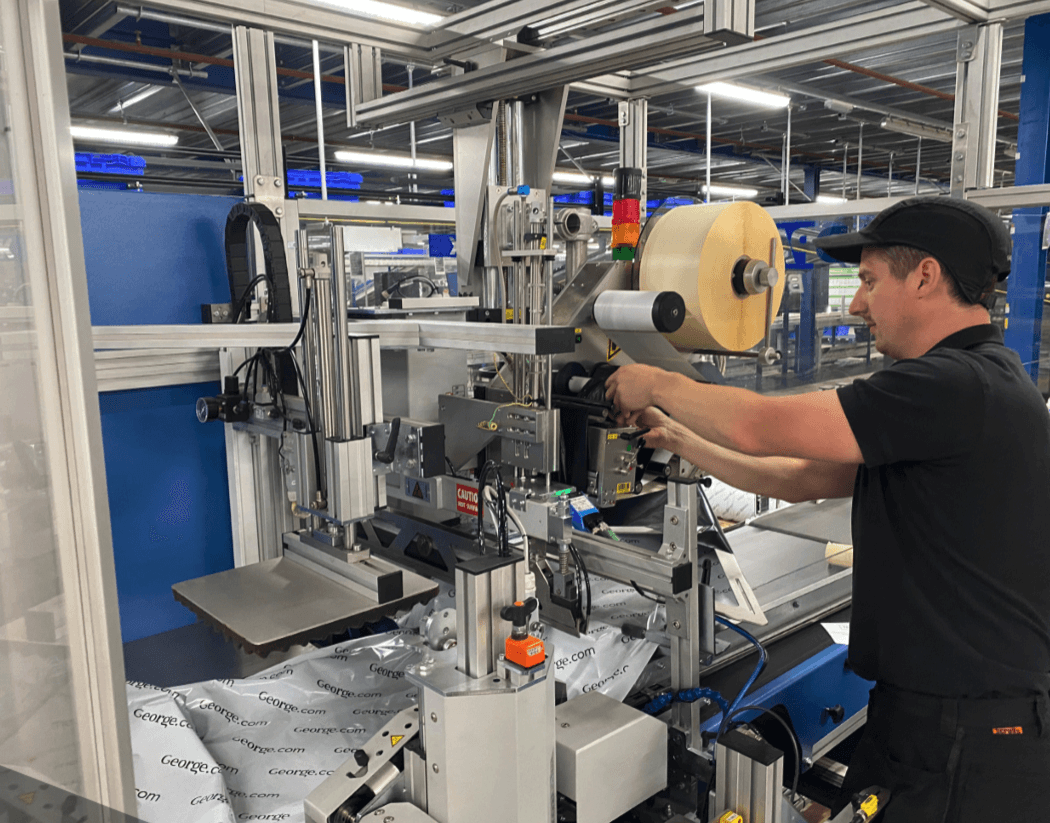

Case study DHL Hams Hall site, Selfridges & Co

The innovative collaboration with DHL at the Hams Hall site demonstrates a profound enhancement in e-commerce efficiency for Selfridges & Co. This strategic development, encompassing three key projects worth £600,000, has revolutionized the facility's throughput capacity and operational layout. Key achievements include seamlessly integrating a multi-floor automation system, boosting daily order processing to 20,000 during peak periods, and significantly augmenting packaging throughput. This case epitomizes the expertise in delivering tailored solutions that align with dynamic market needs.

400,000

sq ft Facility Size

20,000

Per day Order Throughput

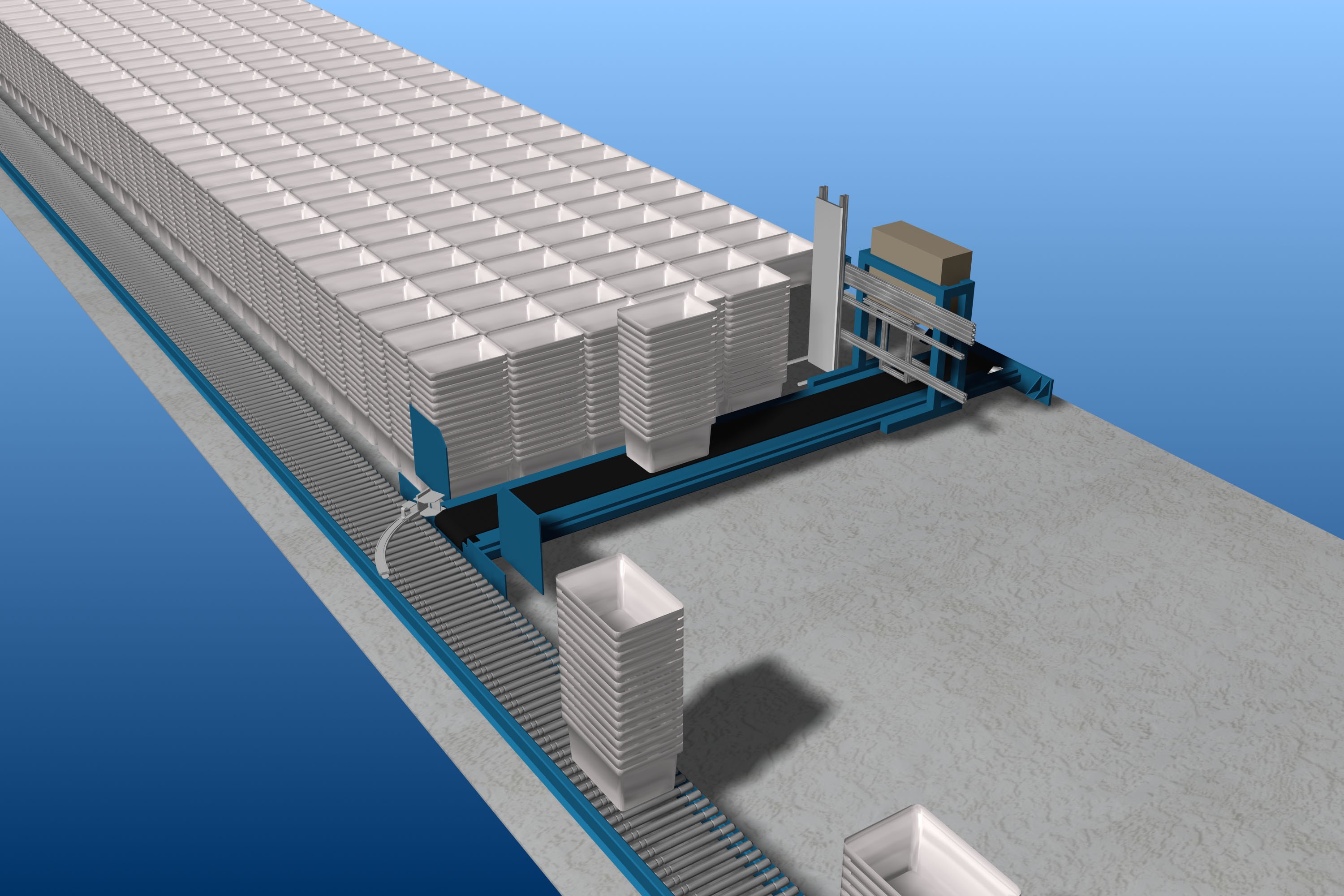

Nekos LT Storage System

In an ambitious project with a large logistics integrator, Nekos expertly implemented the LT Storage (Logistic Tote) system, significantly enhancing the storage capacity and efficiency for a major warehouse. The project exemplified Nekos's capacity to provide advanced, scalable storage solutions that adapt seamlessly to client requirements, optimizing space and workflow within the facility. The LT Storage system has minimum ecological footprint and handles 1.000.000 totes/day globally.

150

Totes/m2 Space utilization

1000

Stacks LT-Storage size